01.09.2025

Latest news

What is system packaging? Advantages for industrial companies

What is system packaging? Advantages for industrial companies

Packaging is much more than just protection for transportation. It is part of the process - especially in industry. System packaging goes beyond the classic folding box, wooden crate or pallet. It is precisely tailored to the product, the transport route and the logistical processes. For many industrial companies, this is a decisive step towards efficiency, product safety and process optimization.

What is system packaging?

System packaging is a holistic packaging concept that takes into account all requirements along the supply chain. Unlike individual packaging, it is not just a product that is packaged in the short term. Instead, the aim is to create durable, coordinated solutions that can be integrated into the company's production and logistics processes or that support or even optimize them.

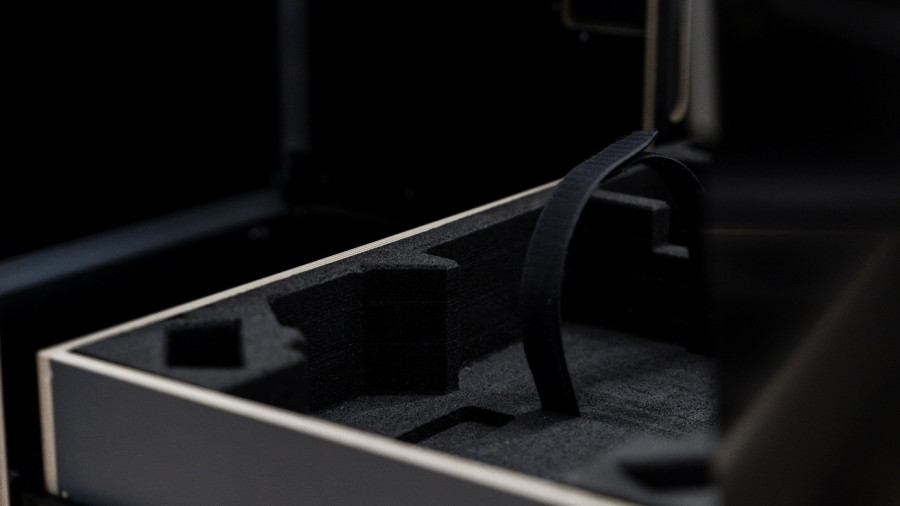

System packaging usually consists of several components - such as a stable base carrier, individual holders or inserts and supplementary packaging elements. It reliably protects the product and at the same time ensures that the packaging and unpacking process runs efficiently and that the costs along the entire logistics chain are lower on balance.

Such solutions are primarily used in industry, for example in mechanical engineering, automotive production or spare parts logistics.

How does system packaging work in practice?

In practice, every system packaging begins with an analysis: Which product should be packaged? How often will it be transported? What are the requirements for storage, handling and return? Do technical or legal requirements have to be met?

Based on this information, packaging experts develop a solution that is precisely tailored to the product. This applies to the dimensions and materials as well as the type of securing - for example, how a component is stored or fixed in the container.

A typical example is the packaging of control units in mechanical engineering. These can be sensitive to vibrations or moisture. Sophisticated system packaging then combines a robust outer carrier with protective inserts made of paper materials or foam that are precisely tailored to the contours of the components. This ensures that everything remains protected - and can be removed quickly for assembly.

These are the advantages of system packaging for industrial companies

System packaging offers a number of specific advantages - both in logistics and in production. They make processes faster, safer and easier to plan.

One clear advantage is the time saved. If packaging and removal are standardized, work steps can be significantly shortened. This is a major advantage, especially for series production or frequently recurring shipping processes.

Product safety also increases. The packaging is designed in such a way that the product is held precisely and protected from movement, pressure or moisture. Damage caused by transportation or improper storage can be significantly reduced in this way.

Another advantage: system packaging reduces the susceptibility to errors. If all components are firmly defined, the risk of incorrect packaging or transport damage is reduced. At the same time, the packaging can be integrated into digital logistics systems - using barcodes or RFID technology, for example.

When is the use of system packaging really worthwhile?

System packaging is particularly useful when products are regularly shipped in the same or similar form. This can be the case in series production or for complex spare parts deliveries that need to be handled reliably and quickly.

The investment is also worthwhile for sensitive or particularly valuable components. This is not just about transport protection, but also about customer confidence in the delivery quality.

The overall calculation is always decisive: system packaging is more expensive to develop than standard solutions. In the long term, however, they save costs - through less waste, reduced packaging time and optimized storage and transport processes.

System packaging at AXXUM: solutions from a single source

AXXUM develops and manufactures system packaging individually for each project. The process begins with a personal consultation in which all technical and logistical requirements are recorded.

A packaging concept is then created that fits seamlessly into the customer's material flow. State-of-the-art 3D planning tools and in-house production capacities are used - for example for CNC-milled inserts, special containers or reusable packaging.

AXXUM supports its customers not only technically, but also organizationally: from development and prototyping to series production.

Conclusion: System packaging as the key to greater efficiency in the industry

System packaging is more than just a means of transportation. It combines product protection with process optimization - across the entire supply chain. They are therefore a strategic success factor for industrial companies that have high quality requirements and want to work efficiently at the same time.

FAQ on system packaging

You might also be interested in

About the AXXUM Group

With more than 60 locations in seven European countries and 1,300 employees, we offer integrated, high-quality solutions that meet all requirements relating to B2B packaging, contract logistics and the transportation of industrial goods.

AXXUM GroupCareer

Career entry? Change of perspective? Career advancement? No matter what drives you, we would like to offer you something: a stable, future-oriented and motivating working environment, smart benefits and attractive social services.

CareerServices

Our services in the field of packaging and logistics solutions: Packaging, Contract Logistics and Innovation.

Services